Made in Germany

EDUR-centrifugal pumps for LPG

EDUR Centrifugal Pumps for Liquefied Gases

EDUR centrifugal pumps play a central role in the production, transport, storage, and distribution of liquefied gases. In their liquefied state, gases can be stored and transported much more efficiently compared to their gaseous form. Liquefaction is achieved either by increasing pressure or lowering the temperature below the condensation point. When needed, the gas can be reverted to its gaseous state through controlled expansion, allowing pumps to supply the gas to end-users as required.

EDUR pumps are essential components in the entire liquefied gas supply chain. In the liquid state, gases exhibit a significantly higher energy density, simplifying transport and storage compared to gaseous form. Liquefaction is carried out by pressure increase or temperature reduction below the boiling point. Controlled expansion then converts the liquid back into gas, which is delivered to the customer using appropriately designed pump systems.

EDUR designs and manufactures centrifugal pumps specifically for liquefied gas applications in production processes, as well as for transportation, storage, and distribution. The pumps are engineered with high gas-handling capability, ensuring reliable performance even when pumping gas-laden liquids. Thanks to low NPSH (Net Positive Suction Head) requirements, EDUR pumps operate cavitation-free, providing dependable flow in both suction and feed operations.

EDUR liquefied gas pumps are available in ATEX-compliant designs. Various sealing systems—such as double mechanical seals or hermetically sealed magnetic couplings—guarantee high operational and system safety.

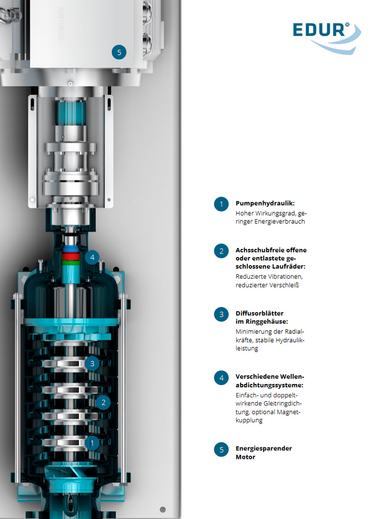

Key Advantages and Technical Features of EDUR Centrifugal Pumps:

- High efficiency

- Axial-thrust-free open impellers or balanced closed impellers

- Compensation of radial forces via diffuser elements in the volute casing

- Low NPSH requirements

- Capable of pumping gas-laden liquids

- High nominal pressures

- Low-pulsation media transport

- Low noise emissions

EDUR LPG pumps

| Modell | capacity m³/h (max.) | Diff pressure bar | connetctions DN (IN/OUT) | requered kW |

|---|---|---|---|---|

| NHKE 404 B150L II2GCT4 | 15 (24) | 6 | 65 / 40 | 5 |

| NHKE 407 B150L II2GCT4 | 25 (35) | 11 | 80 / 65 | 11 |

| NHKE 409 B150L II2GCT4 | 25 (45) | 15 | 80 / 65 | 15 |

| NHKE 603 C160L II2GCT4 | 30 (35) | 6 | 80 / 65 | 7 |

| NHKE 605 D160L II2GCT4 | 30 (45) | 10 | 80 / 65 | 22 |

| NHKE 607 D160L II2GCT4 | 30 (45) | 14 | 125 / 100 | 22 |

| NHKE 603 C160L II2GCT4 | 50 (60) | 6 | 125 / 100 | 11 |

| NHKE 605 D160L II2GCT4 | 50 (60) | 10 | 125 / 100 | 15 |

| NHKE 607 D160L II2GCT4 | 50 (100) | 14 | 125 / 100 | 22 |

| NHE 603 E162L II2GCT4 | 70 (100) | 5 | 125 / 100 | 11 |

| NHE 606 E162L II2GCT4 | 70 (100) | 10 | 125 / 100 | 22 |

| NHKE 1006 G180L II2GCT4 | 70 (120) | 14 | 125 / 100 | 55 |

| HKE 1003 G170L II2GCT4 | 90 (130) | 5 | 125 / 100 | 18 |

| NHKE 1005 G180L II2GCT4 | 90 (130) | 10 | 125 / 100 | 45 |

| NHKE 1003 G180L II2GCT4 | 110 (130) | 5 | 125 / 100 | 30 |

| NHKE 1006 G180L II2GCT4 | 110 (130) | 11 | 125 / 100 | 55 |

| NHKE 1004 G180V II2GCT4 | 160 (170) | 5 | 125 / 100 | 45 |

Other Pumps Available on Request

Thanks to our extensive expertise, we specialize in efficient custom solutions. We select the optimal EDUR pumps for your needs and deliver tailor-made systems designed specifically to meet your individual requirements.